Buying a Screen Printing Machine

Before buying a screen printing machine, it is important to know the basic requirements. A few things to keep in mind are Cost, Assembly, Water-based inks, and features. This article will walk you through these issues if you are new to screen printing. Purchasing a machine is easy once you know how it works and how to make a purchase. You can also look at some tips and tricks to make your printing process go smoothly.

Costs

The costs of setting up your own screen printing business may seem overwhelming. There is a lot to think about, from equipment to inventory to employees and insurance. You should consider all of these factors and your marketing plans. Where will you put your screen printing business? Depending on your type of business, a location in an area with plenty of potential clients may be ideal. Otherwise, you will have to pay rent and hire employees to manage the business.

The cost of setting up a screen-printing machine will vary depending on the amount of clothing you plan to print. Each color in your artwork will require a different screen, which can add up quickly. In addition, the screen-burning process takes 5-8 steps to complete and is not cheap. However, the money you save on labor can be well worth it. A screen-printing machine will be extremely useful for printing large quantities of shirts, so it can help you save time.

Small-scale businesses will likely need a compact and easy machine to move around. They may operate from home or have a small space. Small-scale businesses may also want a lightweight machine and easy to move. Screen-printing presses are made of stainless steel and fairly lightweight. Larger machines may be better if you want to print larger quantities, but they are more expensive than small ones.

Features

A screen printing machine is a device used for producing prints on fabric, paper, or other surfaces. It can perform several functions, including feeding, printing, and drying. The machine may have several patterns and different sizes of screen frame plates. It may be equipped with a vacuum absorbent device, which can enhance the printing quality. It also has a micro PLC control system and human and machine touch control. These features help make screen printing a more efficient process for fabric manufacturers.

A screen printing machine prints on many sheet materials, from ultra-thin flexible plastic to extremely thick and hard surfaces. It can print on paper and cardboard to various plastics, banner vinyl, and even wood. Its flexibility and durability make it the perfect machine for various applications. Ultimately, a screen printing machine can produce high-quality designs. You can even use it for advertising works on lumen or external lighting.

The number of stations is essential when using a screen printing machine with many colors. The number of stations will vary according to the size of your job. Additional stations can be used for flashing, which is the process of exposing a white under-base before printing. Additionally, a larger number of stations means a shorter waiting time. It is also easier to create custom designs with the help of a screen printing machine. However, finding the best one for your needs may be tricky. So, keep these features in mind when buying one.

Assembly

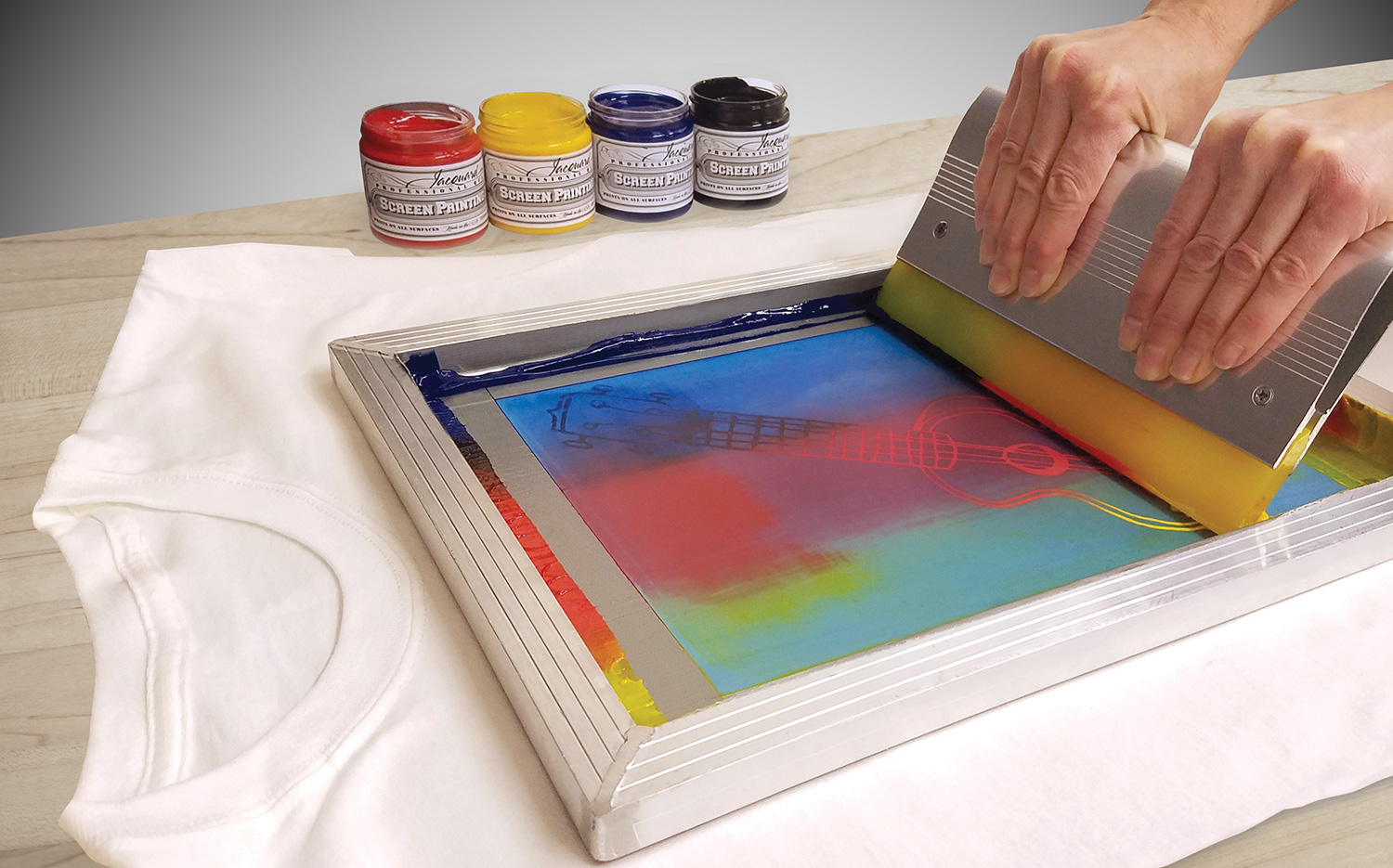

Screen printing machines have several parts. One component is the squeegee assembly. This component is made of a squeegee blade and a liquid-filled tubular member. The liquid exerts pressure along the squeegee blade’s length and width, creating an equalized pressure distribution. The squeegee blade, in turn, creates an ink-like pattern on the printing screen. The squeegee is a complex piece of equipment, and the squeegee holder accommodates many components.

Screen-printing machines typically require multiple colors. Screen registration involves aligning successive screens. This process ensures that the colors do not overlap and are evenly spaced on the screen. If the color placement is incorrect, indicia on the finished product may appear uneven or skewed. Assembling a screen-printing machine requires an excellent understanding of screen printing process theory. Assembly of screen-printing machines requires a diploma in mechanical engineering or a relevant field.

The pallet arm 70 is a central part of printing machine 10. It is attached to a pallet supporting frame 404. The pallet arm 70 has an adjustment mechanism 412 that moves the pallet supporting frame relative to the arm connecting frame 408 in a specific orientation. Once the screen-printing machine is assembled, it is time to test the ink on the first printing press. The screen printing machine may be used to print a variety of products.

Water-based inks

Water-based inks for screen printing machines are good for those looking for a soft-hand feel to the print. These inks can be cleaned with soap and water. You can purchase these in sets or by color. When choosing a water-based ink, make sure to buy the best one for your specific application. It is crucial to use the correct emulsion for all-around printing. The pros and cons of water-based inks are well-defined in our buying guide.

Water-based inks are more environmentally friendly and more durable than plastisol inks. Speedball inks are great for industrial and print studio use because they are non-toxic and low-flammable. These inks dry quickly to a smooth matte finish. They are highly durable and offer superior coverage. Unlike plastisol, water-based inks can be mixed with a transparent extender base for a smoother finish.

Water-based inks produce vibrant, vivid prints. However, if you want to print neon colors on darker fabrics, you must use white ink or use a separate under the base screen. Some manufacturers produce white ink that doesn’t need an under-base. It is suitable for both high-mesh fabric and dark-colored textiles.

Synthetic threads

When selecting threads for your screen printing machine, you need to consider the quality of the fabric. Silk fabric absorbs ink evenly and provides a flat surface for screen printing. Thinner silk fabric will absorb less ink and produce a subtler effect. Silk also tends to move during the printing process. To prevent this, you should prewash the fabric before using it. A table adhesive will also help keep the delicate fabric in place while printing.

Monofilament polyester mesh is available in white and dyed colors. The white mesh will reflect light and refract light past the stencil when exposed, while a dyed mesh will transmit light along white threads and undercut the stencil. Mesh openings for different mesh thread counts are available in various mesh diameters. The low elongation mesh will give you a better print tension and a longer print life.

Fabrics made from synthetics may require special production techniques. To print on synthetic fabrics, you may need to coat the platen surface with paper before printing. It may be necessary to perform regular quality checks. The appropriate ink for synthetic fabrics may be water-based. You also need to learn how to make water-resistant screen materials and set the curing and drying temperatures. Accurate production records are also important.

Sturdiness

While it may be difficult to choose the best screen printing machine for your needs, there are many things you can do to ensure its durability. A 4-color machine will typically weigh around 46 pounds, making it easier to move around. A machine of this site will be suitable for both commercial and recreational uses, and it is large enough to handle larger jobs without creating storage issues. Here are the factors to consider when choosing a screen printing machine.

First, consider the material you plan to print on. A screen printing machine can print on many different materials. In addition to vinyl and fabric, you can use screen printing to print on rigid plastic, foam board, metal, and glass. The durability of your screen printing machine is also important because it can withstand heavy wear and tear. Buying a screen printing machine is also a great investment for your business.

The next consideration is the weight of the machine. A heavy-duty machine will be better if you plan to print large quantities of a single color. You should also consider the weight of the machine before buying it. A lightweight machine will be easier to transport. A screen printing machine that is lightweight and durable will be easier to store and move around. In addition to the weight, you should check its squeegee and the clamps to avoid excessive ink splashing.

Organizing

When it comes to screen printing, it’s very important to organize your workspace properly. A well-organized washout room can make this process much easier. To keep your screen cleaning space organized, first, you should block off the screen part containing the design you want to print. Then, make sure that there are no blank spaces in your workspace. The open spaces are where the ink will contact the substrate.