Different Methods of Denim Printing

When you are looking to make your own shirts, jeans or other items, you can choose between several methods of denim printing. You can choose from Digital printing, Inkjet printing, Laser engraving and screen printing. Each method is easy and fun to use. But if you are looking to print without all the fuss, sponge dabbing is the way to go. You can get different colors from a few colors by sponging them onto clean pieces of sponge.

Inkjet printing

Inkjet printing for denim jeans has recently become a popular way to create jeans. This process has largely replaced screen printing, and has opened up a range of new fashion possibilities. This method of textile printing also requires less water and energy. Although colour and line quality was generally good, they found it difficult to achieve textures. This may be because ink penetrates the denim fabric strongly.

The cost of producing a design can increase as more colors are used, so researchers have tried printing on denim with a variety of different settings. To increase contrast, try increasing the white ink setting. Also, make sure that you increase the CMYK settings to super fine. This setting slows down the printing process but ensures the details are printed over the seams. Once this process is perfected, you can print your denim items with confidence!

Inkjet printing for denim has many benefits. Because it’s a print-on-demand process, it uses less energy and water. Another major benefit is that it offers limitless colors. In traditional printing, more colors add to the cost, but in inkjet printing, there’s no limit. This allows you to create designs of unlimited colors. You can even make denim jeans with a variety of designs, so you don’t have to worry about running out of colors!

Another option for printing denim is laser engraving. Laser engraving offers the same benefits of inkjet printing, including unlimited patterns and colors. Moreover, laser engraving is also energy-efficient and requires less labor. It reproduces the traditional effects of denim finishing while preserving the garment’s colour. This is the best option for printing denim garments. It’s an efficient and cost-effective option for printing denim garments.

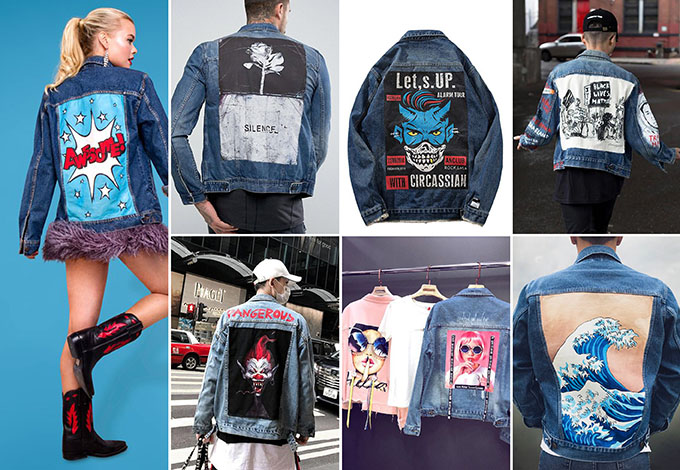

Digital printing allows for greater creativity. Designers can develop unlimited motifs and patterns and print them on denim fabrics. In addition to this, they can now work closely with retail distribution networks, and materialize their fast fashion concept with the help of digital printing. This can help companies compete in the fast fashion industry. The benefits of digital printing for denim include reduced labor costs and increased creative freedom. You can now design denim garments that are environmentally friendly while still looking great.

Digital printing

The new technique of digital printing on denim fabric gives designers greater creative freedom. A wide variety of motifs and patterns can be developed and printed on denim fabric, allowing designers to work more closely with retail distribution networks. The technology can materialize a fast-fashion concept and boost a company’s competitiveness. In addition, digital printing allows for much smaller production runs. Here’s how digital printing for jeans works. It can reproduce denim-like quality from fabrics that are more expensive and harder to dye.

The digital printing process is much the same as on T-shirts, but there are subtle differences that can make the print stand out from the denim. Using the true view feature on the printer helps you see the end result. The print will be slower, but you’ll get more detail and coverage over seams. This is the most basic tip on digital printing for jeans. It’s worth a try!

While screen printing is a faster and more versatile option than digital printing, there are some drawbacks to the technique. For instance, it may not work well on 50/50 cotton/polyester blends. Also, the color of the fabric can cause issues, resulting in dye migration. The dye on the garment will bleed into the ink, resulting in a dingy-looking print. In contrast, screen printing works on any fabric, even fluorescent colors.

When it comes to printing jeans, one of the biggest challenges of digital printing is that of achieving the right placement. Traditionally, direct-to-garment printing can’t reach specific placements, like a 1” spot on the upper back. However, screen printing is more flexible, as it can print on the entire garment, including the pant leg, hood of a hood, and side prints. With digital printing for jeans, the options for printing jeans are endless!

Laser engraving

While traditional methods of denim printing require the use of chemical reagents to fade the dyes, laser marking processing has several benefits. It significantly reduces water consumption and pollution from the manufacturing process. This makes it an environmentally friendly and economic solution. Here are some of the advantages of laser engraving for denim printing.

It can produce many personalized and traditional effects on denim. Its ease of operation and stable quality make it a popular choice for denim engraving. Moreover, laser-marked patterns have a distinct and soft hand feeling. The images produced by laser engraving are rich in variation and will never fade. Golden Laser has a seasoned sales team, a consultant team, and an after-sales service team that will help you make the right decision.

Moreover, the flat engraving trace of the PRONOUNCE fabric makes it easy for you to create unique designs on denim. The team behind the technology has used high-density denim fabric as a base, as well as denim craftsman’s techniques to make the product look unique. This method allows you to apply finishing effects and change the appearance of denim garments without affecting the strength of the fabric.

Apart from being environmentally friendly, laser engraving for denim printing also provides benefits for the environment. Digital laser processing is a good option for denim garment factories because it saves both energy and water. Apart from being cost-effective, this technology can create 3D effects or even tattered, worn-out looks. Moreover, laser engraving for denim printing is compatible with the current green economy. It is easy to operate and does not require a lot of energy.

With laser engraving, the markings created are permanent. They are darker in color and are permanent. The depth of the markings can reach up to 0.5 mm. In addition, laser engraving has two methods of creating contrast: one faster method etches the black marks onto the bare material, while another takes longer. It also enables a combination of white and black markings. Denim manufacturers prefer the second method.

Screen printing

If you’re in the market for a new pair of jeans, you should consider the benefits of screen printing for denim. This process can be done on both denim jeans and 100% cotton shirts, and can even be used on denim jeans that are not machine washable. Digital printing requires a low amount of colorant, and is also eco-friendly because it uses less energy and water. This method of printing allows for a variety of designs, including those that are not available on denim jeans.

There are three different ways to screen print a denim shirt. One method uses a mesh screen and a squeegee to apply the ink. Another method is a press, which holds the screen in place between prints and makes it easier to change out clothing and paper. There are two types of presses – manual and semi-automatic. Each type has different advantages and disadvantages.

Several techniques are available for screen printing. The basic technique involves creating a stencil made of transparent acetate film. A specialised ink is used to print on other surfaces. When the stencil is ready, the item is laid flat on the printing board and under the screen. For most modern commercial printers, a rotary carousel printer is used. This printer allows several screens to work simultaneously and can apply separate colour layers in quick succession.

The other common method of screen printing is using stencils. This process can be used for both commercial and artistic purposes. Because one stencil can be used to produce many items, screen printing allows for more intricate designs and more colours than digital printing. The limitation of screen printing is its limitations, but the process is very efficient. Screen printing for denim is one of the most affordable ways to get a high-quality, durable denim shirt.